LSP series

(Universal rolling brush deburring, surface drawing, chamfering blunt equipment)

Main processing scope of the equipment

Processing products: carbon steel, stainless steel, aluminum plate, copper plate, all kinds of non-ferrous metals, etc

Equipment function:

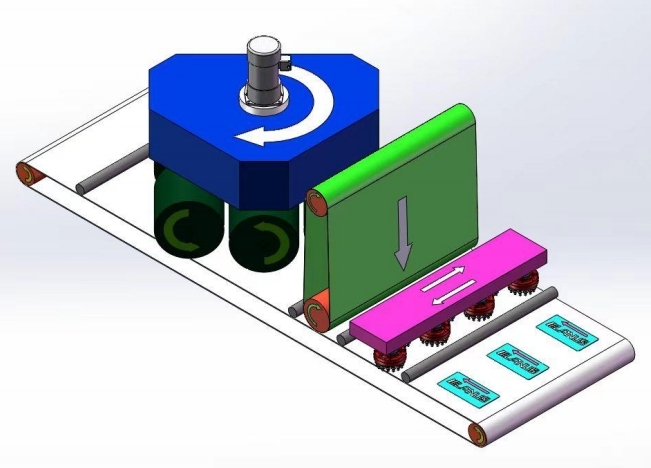

This equipment is a dry type combination of one set of hammers disk, one set of sand belt and six sets of universal roller brushes.

It is mainly used to process the edges of workpieces, slag hanging in holes, deburring, and achieve hair lines, scale removal, and

polishing of metal plates. Wait for processing. For stamping, shearing, laser cutting, plasma cutting, flame cutting and other

processes, burrs can be removed in all directions, so that all edges, corners and holes can achieve a R arc effect.

The processing process is safe and reliable, so that the workpiece reaches perfect quality.

The steel hammer and disc brush station removes slag from the workpiece surface.

The sanding belt removes large burrs and slag particles on the surface.

The roller brush removes burrs and chamfers the edges and inner holes of the workpiece.

Each station can also be used independently.

Main technical parameters of the equipment

working width ≤800mm ,1000mm; 1350mm; 1600mm

Processing thickness 0.5~80mm

Minimum processing size 50mm×50mm

Four-column synchronous lifting, rolling brush position independent lifting, lifting servo control, accuracy 0.01 mm.

Machine NC PLC touch screen adjustment processing parameters.

Matching wet vacuum cleaner or industrial pulse vacuum cleaner to treat grinding dust to achieve environmental protection production

Optional feeding mode:

1. Strong permanent magnet adsorption transport feed (suitable for carbon steel workpieces. Workpiece size ≥10 mm×10 mm)

2. Vacuum negative pressure adsorption conveying feeding (suitable for stainless steel plate, copper plate, aluminum plate, etc.) is not magnetically adsorbed. Workpiece size ≥50 mm×50 mm)

Equipment diagram:

Basic equipment parameters: